Hamilton Issued about 30 technical documents (TD’s) prior to WWII. I plan to use post each one in a readable format. Age rendered the TD’s difficult to read and understand.

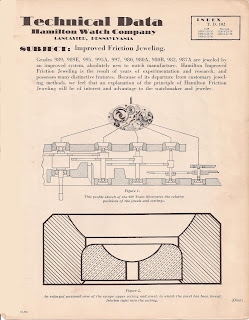

Grades 989, 989E, 995, 995A, 997, 980, 980A, 980B, 982, 987A are jeweled by an improved system, absolutely new to watch manufacture. Hamilton Improved Friction Jeweling is the result of years of experimentation and research, and possesses many distinctive features. Because of its departure from customary jeweling methods, we feel that an explanation of the principle of Hamilton Friction Jeweling will be of interest and advantage to the watchmaker and jeweler.

Figure 1. This profile sketch of the 989 Train illustrates the relative positions of the jewels and settings.

Figure 2. An enlarged sectional view of the escape upper setting and jewel, in which the jewel has been forced friction tight into the setting

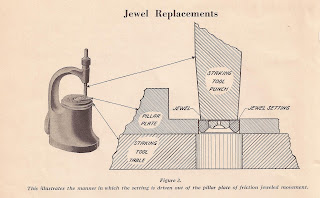

Figure 3. This illustrates the manner in which the setting is driven out of the pillar plate of friction jeweled movement.

When replacing a broken jewel in a friction jeweled movement, all that is necessary is to drive out the entire setting as illustrated in Figure 3, using a standard staking set with a flat face punch smaller in diameter than the setting to be removed.

The settings are held in the plates and bridges friction tight.

With friction jeweling the repairman’s task becomes very simple. He orders the complete setting needed — such as third upper, escape lower, or whichever one is to be replaced – for the size and grade stamped on the bridge. When this is procured, he simply pushes out the old setting and pushes in the new, thus eliminating the chucking, centering, truing, bezeling, facing, inserting, flushing, shouldering, backing-off and stripping which ordinarily are necessary.

These new jewel settings should be driven in the plates and bridges from the inside. The chamfered corner serves as a guide in locating the setting before it is driven to its position. Should the endshake be too short, either lower or upper setting can be driven out. In the same manner either setting can be driven in should the endshake be too long.

Copyright 2006-2017 | All Rights Reserved