T. D. 103 Hamilton Watch Company LANCASTER,PENNSYLVANIA

SUBJECT: Semi-Friction Balance Jeweling

NOTE: This type of balance jeweling will be found in grades 986A, 987 987E, 987F, 989 and 912.

Fig. 1, shows a cross-section of the movement through the center line of the balance. This drawing represents the balance bridge, pillar plates, hole jewel and endstone setting cut in half and the jewels and staff in their natural position.

To Replace the Upper Balance Settings

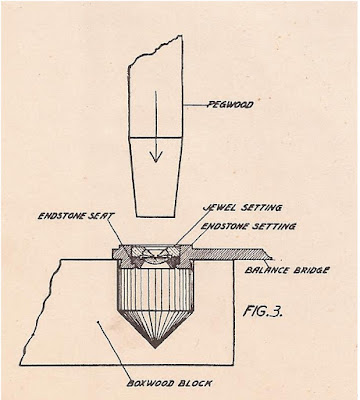

Figure 3

Place the balance cock top side down on a piece of boxwood or on the balance bench (Fig. 3.) Put the endstone in place and press tightly against the “seat,” using pegwood smaller in diameter than the body size of the setting. The endstone setting should fit freely in the hole. Next, put the hole jewel setting in place and press down tight against the endstone. This setting should fit friction tight in the hole, holding the endstone securely in place.

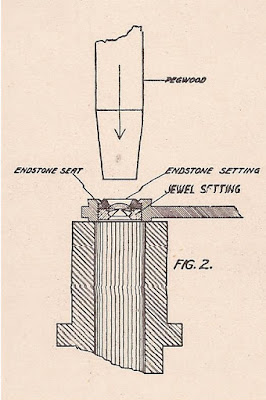

To remove the upper balance settings

place the balance cock over a stump of a standard staking set in which there is a hole larger in diameter than the setting. Use a piece of peg wood with a face diameter slightly smaller than the endstone setting diameter and press both the endstone and hole jewel out of the cock at the same time. Some watchmakers prefer steel, nickel or brass punches to remove and replace the jewel settings. This is optional as care must be exercised with any style of punch.

Tightening jewel settings

If the whole jewel does not fit tight enough in the hole to hold the endstone setting in place it may be “spread” (see Fig. 4) using a hollow punch from a standard staking set. If care is exercised in removing the settings it will never be necessary to “spread” them.

Figure 4

Copyright 2006-2017 | All Rights Reserved