Many Lives Sacrificed Because of Faulty Watches

New York Tribune, January 10, 1910 by James B. Morrow

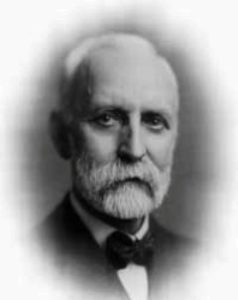

An unseen man, whose name, if mentioned, has made, perhaps, no impression, is helping the green lights, the white lights and the red lights, the wooden arms that reach across the tracks, the rail makers, the car builders and the train dispatchers to make travel both swift and safe by day and night.

It may be, in the way of protecting life and in the matter of saving legs and arms, not to mention heads, necks and backs, that Webb C. Ball, time expert on 125,000 miles of railroads, is beating all the hospitals in the United States and most doctors besides. It may be.

If one’s watch were thirty seconds slow or fast, it would make no appreciable difference in the routine of one’s pleasure or schedule. Measured in feet, however, thirty seconds equal half a mile and more to the locomotive engineer of a high velocity special or twentieth century flyer. A half-mile either way from the approximate spot of the running schedule might mean one hundred lives and a property loss of many thousands of dollars.

It is Mr. Ball’s duty to see that the watches of engineers and conductors from New York to San Francisco and from Chicago to New Orleans are so nearly exact month in and month out that sideswiping and collisions, head-on and from behind, are at least theoretically impossible if orders are obeyed and signals rightly read and not disregarded. Nearly all the good railway systems of the United States have put the technical details of their time into his management. He has offices in Cleveland, Chicago and San Francisco, and his assistants are travelling the country constantly.

Ultimately, of course, some man would have thought out his scheme of watch and clock inspection – as some other men than Morse would have invented the telegraph – but to Mr. Ball alone as a pioneer belongs the honor of its conception and perfection. “When did you begin,” I asked, “to regulate the watches and clocks of railways?”

Bad Watches Caused Wreck

“Eighteen years ago there was a bad wreck on the Lake Shore and Michigan Southern Railroad,” Mr. Ball answered. “The Fast Mail, known as No.4 was going east. An accommodation train was coming west. At Elyria, twenty-five miles from Cleveland, the engineer and the conductor of the accommodation were given orders to let the fast mail pass them at Kipton, a small station west of Oberlin, the university town. As the accommodation was leaving the station at Elyria the telegraph operator ran to the platform and verbally cautioned the engineer and conductor, although both men had been given orders in writing.”

‘Be careful,’ the operator shouted. ‘No. 4 is on time.’

‘Go to thunder,’ the conductor called back. ‘I know my business.’

“From the time the train left Elyria it collided with the fast mail at Kipton the conductor, as he admitted afterward, did not take his watch out of his pocket. He said that he supposed the engineer would look out for No.4. But the engineer’s watch stopped four minutes, and then began running again, ‘a little matter of life and death of which he was unconscious. There were several stations between Elyria and Kipton, but the engineer pounder slowly along in the belief that he had time to spare. Leaving Oberlin, he supposed he had seven minutes in which to reach the meeting point. Of course, he had only three minutes. Had the conductor looked at his own watch, he could have prevented the accident.

“The trains came together at Kipton, the fast mail at full speed and the accommodation under brakes, because it was nearing the station. The engineers of both trains were killed, and the dead bodies of nine clerks were taken from the kindling wood and broken iron of the postal cars. The railroad sustained a heavy loss in property, and a large quantity of mail matter was either lost or destroyed. There was an official inquiry into the wreck, and the coroner of Lorain County summoned me – as an expert in watches. I might say. The case was finally carried into the United States court at Toledo, and I went there several times to testify.

Finds Variable Time

“Returning to Cleveland on one occasion with John Newell, president of the Lake Shore road, and William H. Caniff, the superintendent, I suggested a plan of watch inspection. The Kipton accident proved that the watch of one of the engineers was unreliable, and that the conductor of the accommodation train had neglected his business. A meeting of the operating officers of the railway was held soon after, and I was authorized to get up a scheme of inspection and also to investigate conditions on all the important lines east of Chicago.

“I found that the conductors on the freight trains of trunk lines were depending on cheap alarm clocks hung on nails in the cabooses. Many merchants at that period were giving away bad watches with suits of clothing and furnishing goods, and engineers and conductors had such watches in their pockets, and were actually running trains by them, to menace of human life and property. Some of the clocks in roundhouse and in train dispatchers’ offices hadn’t been cleaned, repaired or regulated for years. The rule then – and I suppose it prevented many frightful wrecks – was to give conductors and engineers five minutes extra on their orders; that is to say, a train due at 10 o’clock would be safe if it arrived at 10:05 or 9:55 o’clock.

“If one of the fastest limited trains now running on two roads from New York to Chicago is thirty seconds off its time, the conductor must report the fact at the first stop. I timed a fast train not long ago. We left Chicago on the dot to Elkhart, Ind., thence to Toledo, thence to Albany, thence to Springfield, Mass., and finally to Boston, where we arrived on the second, after travelling hundreds of miles and changing engineers and engines eight different times. I hope I am not in bad taste when I say that the watches of the ten engineers and ten conductors of that train were regulated and inspected by my own men. Without watches of absolute precision, and dependable at that, eighteen-hour trains between Chicago and New York would be an impossible achievement.

“But I have wondered away from my story,” Mr. Ball went on to say.”After an investigation that covered four months, I got my plans concretely formed and put them into operation. Local time inspectors, the best mechanics obtainable, were appointed at the end of every division on the Lake Shore road. Conductors and engineers were required to have their watches examined every two weeks. If a watch fell behind or gained thirty seconds in fourteen days it had to be repaired or regulated immediately. Small cards were given to engineers and conductors and complete records of their watches were written down in ink at least once in two weeks by official inspectors.

“Since then necessary details have been added to the plan, but the fundamental requirements have not been changed. Every conductor and engineer on the 125,000 miles of railroads where the plan is operative carries a little card in his pocket containing a full description of his watch and a technical history of its fortnightly performances. When he leaves his watch for repairs or regulation the inspection the inspector gives him a “loaner watch,” as it is called, that is guaranteed to keep times to the to the fraction of a second.

“As the scheme developed, I passed upon certain kinds of watches. The manufacturers who had to be excluded from the acceptance list threatened to sue me fir damages, and for slanders and decline a good many benevolent suggestions. I now approve thirty-seven different kinds of watches that are manufactured in eight separate establishments.”

“Do all railroads have similar schemes of time inspection?” I asked.

“I suppose so. A man, copying some of the features of my plan, got on to an important road not long ago, and sold twelve thousand watches to the employees, getting $45 apiece for watches that cost him $5.

Then the officers of the road fired him and sent for me. Several years ago forty passengers were killed on one of the biggest railways in the country. It was a case where the watches of the engineers and conductors did not agree, and all were wrong, I guess. I was called by telegraph to organize the line.

“An assistant whom I sent the road as a telegraph operator in search of a situation learned that the clock of the operating headquarters was forty-five years old. Indeed, the clocks at telegraph stations and signal towers up and down the line and on all the branches were absolutely impossible for the purposes intended. The watches of the conductors and engineers were almost as bad. I threw away the clocks and condemned the watches, and if orders are obeyed there will be no more collisions on that particular road. The accident also cost the life of the general manager of the company. He died soon afterward of a broken heart.

“No one will ever know,” Mr. Ball continued, “how many people have been killed because of worthless watches. In the old days, when watches went by hitches and jerks and there was no attempt at time inspection, the causes of accidents were covered up or denied altogether, and the public had to be satisfied with nothing more definite than its own guessing. Only recently several persons were killed in a collision because the engineer was running his train by a watch borrowed that morning from a female member of the house hold.

Sometimes Reads Wrong

“Occasionally an accident occurs because an engineers with a closed watch removes the case that is over the dial that he may see the hands and face and know the time at a hurried glance. The stem of an open-faced watch, you understand, is opposite the figure 12, while in a closed it is opposite the figure 3. Thus if an engineer forgets himself, he may wrongly read his dial, and serious trouble is almost sure to follow. Not long ago a freight engineer with a watch so change mixed his hands and his figures and made a mistake of fifteen minutes. Rounding a curve, he went head-on into another train, with fatal results to several employees and the wreck of two engines.”

“Would it be practicable for railways to buy good watches and to issue them to its men whenever they go on duty?” I inquired.

“The Pennsylvania Railroad made such an experiment, but gave it up. Men were careless with the watches, and in some instances took them to pawnshops. The railroad employee is never compelled to supply any of the tools with which he works. In that respect, he is favored over the carpenter, the mason and the ordinary mechanic. It is believed, however, that he ought to own a watch and, being his personal property, he will take care of it and have pride in it. I see that he is not overcharged, that he can pay his debt in installments, and that his repair bills are always reasonable.”

“What does a standard railroad watch cost?”

“A filled case – that is, a case with a sheet of gold on the outside thick enough to wear for twenty-five years – and a standard movement can be bought for $40. Fifteen years ago such a watch would have cost $85. There are many thousands of watches of the kind I have described that will not vary ten seconds in two weeks. The watches that I approve are adjusted to temperature, ranging from 30 degrees to 95 degrees, because the balance wheels of brass and steel change with heat and cold. They are also adjusted to five different positions. All standard railroad watches must contain at least seventeen jewels; some are made with nineteen and some with twenty-one jewels – any more would be useless. A watch manufacturer, several years ago, advertised twenty-six jewels – he screwed in the extra jewels as a tailor might sew extra buttons on a coat. His talk sounded well and his watch looked rather gay, but the 30 cents’ worth of additional jewels that he sold to railroad men for $3 were of no utility whatever. I had a long fight with him, but I compelled him to conform to my requirements.

“The jewels of a watch,” Mr. Ball explained, “are its bearings. They are made of rubies or white sapphires, and the holes in some of them are so small that they cannot be seen with the naked eye. Most of them come from Switzerland, the ancient centre of the watchmaker’s guild, where the fine touches of art are passed on from father to son, generation after generation. Americans are too impatient and in too much of a hurry to bore invisible holes in rubies and white sapphires that are smaller than the head of a pin. Besides, the wages of the Swiss watchmaker average only 7 1-3 cents an hour.

“We annually buy about $2,500,000 of Swiss watches and watch parts, the enameled cases from that country being especially artistic and the main springs and dials being unusually good. Certain parts of the best Swiss watches are still made by hand, both in the homes of the workmen and at the numerous factories of Berne and Neuchatel. But American clocks are unquestionably the finest in the world, although the Germans make a clock that sells for $1,500.

“Watches were never so cheap as now and never so accurate,” Mr. Ball said. “I am sure that the standards I have established for railroad purposes have greatly helped to bring the American watch to its present state of regularity and precision, which is good for the man who stays at home, but is infinitely better for the man who travels.”

Copyright 2006-2017 | All Rights Reserved